Challenge

WFI (water for injection) pumps and AHUs (air handling units) are critical to ensuring sterility in pharma manufacturing. Failing to anticipate an issue with a motor on WFI pumps or AHUs could cause batch loss or production shutdowns. Batch losses cost time and money, especially when manufacturing products like biologics with expensive APIs (active pharmaceutical ingredients).

Approach

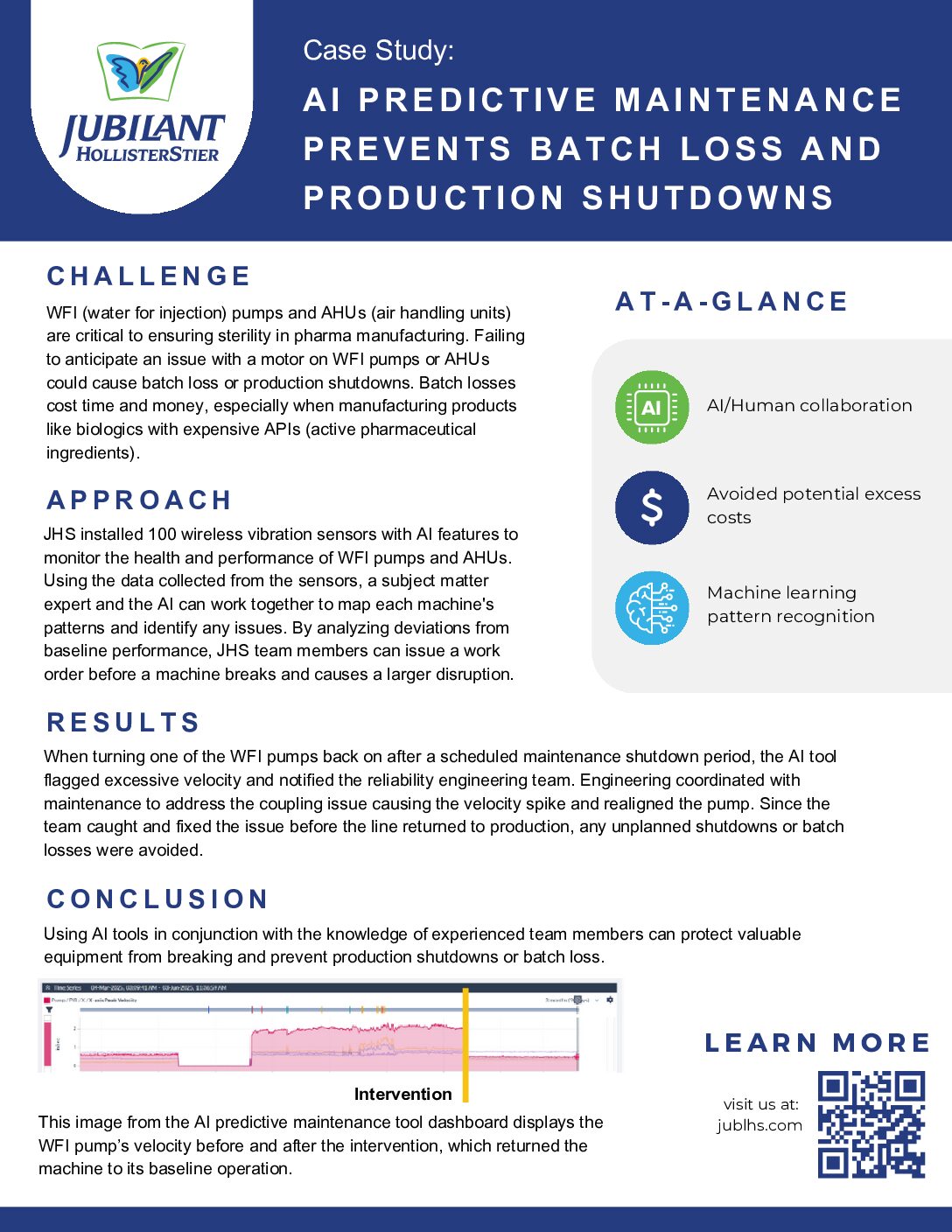

JHS installed 100 wireless vibration sensors with AI features to monitor the health and performance of WFI pumps and AHUs. Using the data collected from the sensors, a subject matter expert and the AI can work together to map each machine’s patterns and identify any issues. By analyzing deviations from baseline performance, JHS team members can issue a work order before a machine breaks and causes a larger disruption.

DOWNLOAD THE PDF TO READ THE FULL CASE STUDY