Pharmaceutical contract manufacturers play a vital role in bringing potential life-saving products to market. With the intricate and complex aspects that come with manufacturing these products, it’s important that guidelines are set and met to maintain safety for future consumers. These guidelines are called Good Manufacturing Practices, which are not only a regulatory requirement, but a commitment manufacturers make to safety and patient well-being.

A Brief Overview of Good Manufacturing Practices

Good Manufacturing Practices (GMP) encompasses a set of guidelines and regulations that ensure pharmaceutical products are consistently produced and controlled to the highest quality standard. They are meant to promote human health and to improve the quality of life for consumers and patients.1

These standards are established and controlled by regulatory agencies such as the U.S Food and Drug Administration (FDA) and European Medicines Agency (EMA). GMPs are a compilation of various guidelines decided by these regulatory agencies that are meant to guarantee the highest standards of efficacy, quality and safety when manufacturing products for the health of the public.1

Why is GMP Important?

According to the World Health Organization, GMP ensures that the processes necessary for production and testing are clearly defined, validated, reviewed, and documented and covers legal components, responsibilities for distribution, contract manufacturing and testing, and responses to product defects and complaints.3

Historical Background

This overhaul resulted in the 1938 Federal Food, Drugs, and Cosmetics Act (FDCA), which provided a higher standard of quality for consumer products.2 The FDCA is what provides the regulatory basis for the current consumer GMP, specifically relating to food. The FDA began monitoring the quality of pharmaceutical manufacturing in the 1960’s and the cGMP was developed after the FDA oversaw the testing of 4600 pharmaceuticals between 1938 and 1962.8

According to the World Health Organization, their first text on GMP was adopted in 1968. The first version of the WHO Certification Scheme that detailed the guidelines for the quality of pharmaceutical products distributed on the global market was accepted into the WHO GMP in 1969.3 The WHO later added a supplementary annex on biological medicinal products in 1991 that established the general approach to the quality of biological medicines.3

The Key Principles of GMP

According to Reis, Catarina P, et al., there are seven key principles of GMP that help define the implemented guidelines:

- Quality management

- Personnel

- Premises and equipment

- Documentation

- Production

- Quality control

- Complaints and product recall

Quality Management

Quality is at the center of all cGMP in various ways. Quality management or assurance includes all matters that influence the quality of a product, management of raw materials, products and/other components, services related to production, management, and production and inspection processes. Quality management is applied to both pre-production and manufacturing production. There are two main principles to quality management and assurance: “fit for purpose”, which ensures that the product is suitable for its intended purpose, and “right first time” which ensures that mistakes are strongly eliminated.1

Personel

A skilled and knowledgeable workforce is essential when it comes to GMP compliance. Each pharmaceutical contract manufacturer must ensure that every employee is trained in GMP requirements and best practices. Personnel who work in manufacturing, quality control, and quality assurance must always be qualified and trained to perform their duties effectively.

Premises and Equipment

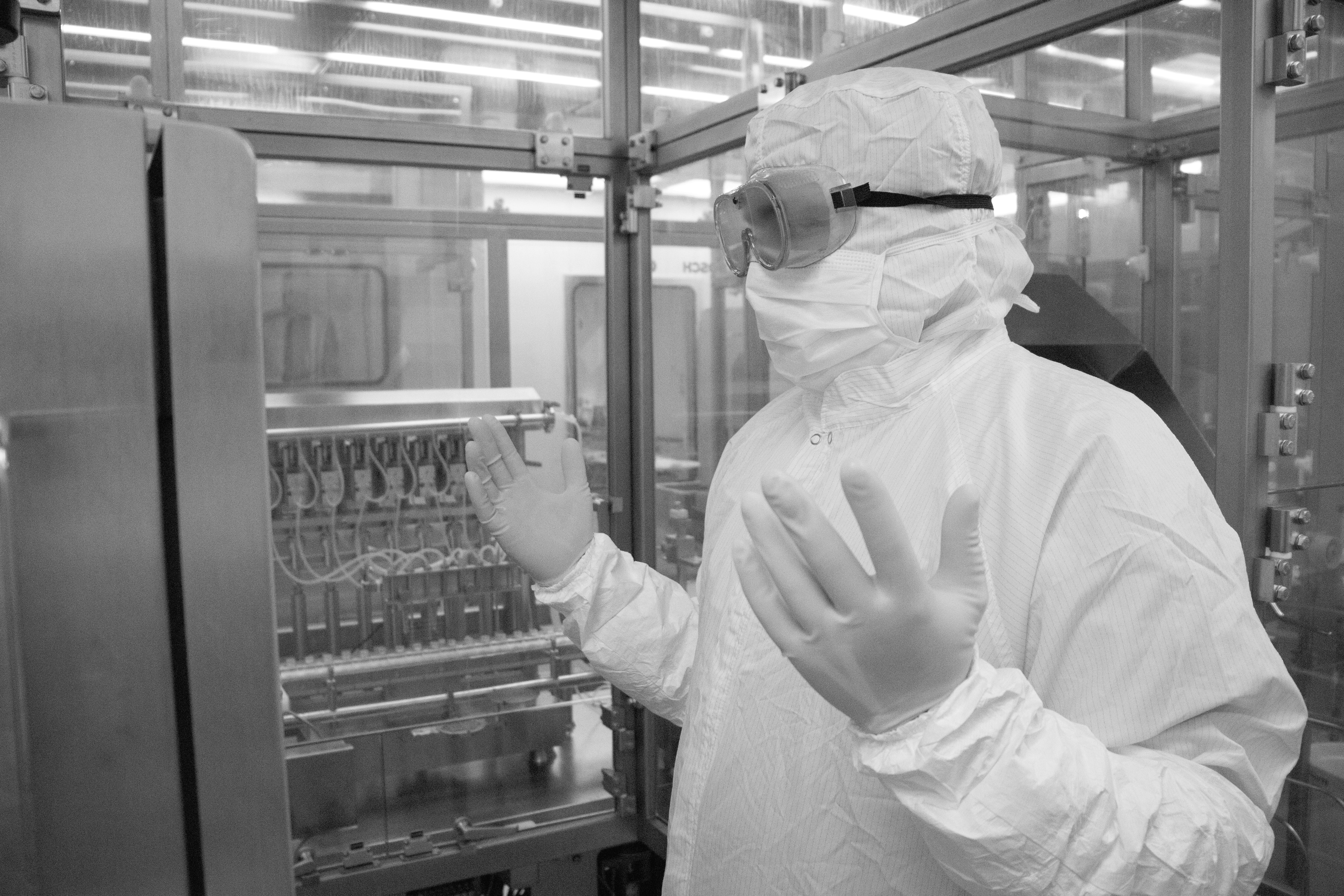

GMP compliance includes facility compliance and quality assurance. Contract manufacturers must maintain facilities designed, constructed, and maintained to ensure proper manufacturing of pharmaceutical products. The facility and equipment must meet and comply with all regulatory agency rules to minimize the risk of errors.1

Documentation

Accurate and detailed documentation is a cornerstone when it comes to GMP compliance. Documentation is an essential part of the quality assurance system and is fully defined in the manufacturer’s Quality Management System.1 Contract manufacturers must have comprehensive records of all aspects of the manufacturing process, from production and testing to product distribution. Regulatory agencies will refer to this documentation when auditing a facility for compliance.

Production

All production must be compliant with the GMP as well. Production must be performed and supervised by trained individuals following the cGMP. All materials and products that are handled during production, like sampling, storage, labeling, processing, and distribution must be done in accordance to GMP procedures and documented.1

Quality Control

Quality control is a fundamental aspect of GMP compliance as it ensures that every aspect of the production process meets the required standards. It involves a series of systematic procedures, checks and assessments designed to monitor and maintain the quality of raw materials and finished products. Quality control is involved in all decisions that concern the quality of a product that will be distributed to the consumer.1

Complaints and Product Recall

The final aspect of GMP is for the manufacturer to have a system that can promptly and effectively recall products that are known or suspected to be defective.1

The Future of GMP and Contract Manufacturing

As the pharmaceutical industry continues to evolve, so must the requirements for GMP compliance. Regulatory agencies will continue to update the cGMP as technology progresses. Automation and data analytics are becoming increasingly important in the pharmaceutical manufacturing industry, and contract manufacturers will need to adapt to these new technologies, while ensuring the final product remains safe for consumer use.

GMP is the foundation of quality when it comes to pharmaceutical contract manufacturing. By adhering to GMP guidelines and regulations, contract manufacturers and their partners will continue to ensure the safety, quality, and efficacy of the products they produce. GMP compliance will continue to be a vital aspect of pharmaceutical manufacturing to ensure the safety of patients and product quality. Learn more about how JHS commits to quality practices, regulatory compliance, and cGMP to ensure every project is a success today and reach out to our team to start your next project.

Article References

- Reis, CatarinaP, et al. “Good Manufacturing Practices for Medicinal Products for Human Use.” Journal of Pharmacy and Bioallied Sciences, vol. 7, no. 2, 2015, p. 87, https://doi.org/10.4103/0975-7406.154424.

- Nutrition, Center for Food Safety and Applied. “Good Manufacturing Practices for the 21st Century for Food Processing (2004 Study) Section 1: Current Food Good Manufacturing Practices.” FDA, 13 Mar. 2020, www.fda.gov/food/current-good-manufacturing-practices-cgmps-food-and-dietary-supplements/good-manufacturing-practices-21st-century-food-processing-2004-study-section-1-current-food-good.

- World Health Organization. “Good Manufacturing Practices.” Www.who.int, www.who.int/teams/health-product-policy-and-standards/standards-and-specifications/gmp#:~:text=Good%20Manufacturing%20Practices%20(GMP%2C%20also.

- Research, Center for Drug Evaluation and. “Facts about the Current Good Manufacturing Practice (CGMP).” FDA, 16 Feb. 2024, www.fda.gov/drugs/pharmaceutical-quality-resources/facts-about-current-good-manufacturing-practice-cgmp.

- “Good Manufacturing Practice | European Medicines Agency.” Www.ema.europa.eu, www.ema.europa.eu/en/human-regulatory-overview/research-development/compliance-research-development/good-manufacturing-practice#ema-role-10392. Accessed 1 May 2024.

- Patel, K.T., and N.P. Chotai. “Documentation and Records: Harmonized GMP Requirements.” Journal of Young Pharmacists, vol. 3, no. 2, Apr. 2011, pp. 138–150, www.ncbi.nlm.nih.gov/pmc/articles/PMC3122044/pdf/JYPharm-3-138.pdf, https://doi.org/10.4103/0975-1483.80303.

- —. “Facts about the Current Good Manufacturing Practice (CGMP).” FDA, 16 Feb. 2024, www.fda.gov/drugs/pharmaceutical-quality-resources/facts-about-current-good-manufacturing-practice-cgmp#:~:text=Pharmaceutical%20Quality%20affects%20every%20American.

- Almeter, Philip J., et al. “FDA Approaches in Monitoring Drug Quality, Forces Impacting the Drug Quality, and Recent Alternative Strategies to Assess Quality in the US Drug Supply.” Journal of Pharmaceutical Innovation, vol. 17, no. 2, June 2022, pp. 269–282, https://doi.org/10.1007/s12247-022-09659-5.