The process of lyophilization, or the freeze-drying of pharmaceutical products including biologics/biological products, has been used in the food and pharmaceutical products including biologics/biological products, has been used in the food and pharmaceutical industries to preserve and stabilize drugs since the 1940’s. For over 80 years, lyophilization has played a significant role in the safe development and retention of vaccines, antibiotics, and small molecules for wide-spread distribution. Lyophilization results in biologic powders that have long-shelf-lives and that can be reconstituted into functioning product as needed and are now an essential part of pharmaceutical manufacturing.

This article provides a comprehensive overview of the lyophilization process, from its fundamental stages to its application in pharmaceutical manufacturing. We’ll explore the intricacies of the freeze-drying process and explore the advantages and disadvantages of this pivotal technology in pharmaceutical manufacturing. Lastly, we will review JHS’ commitment to innovation and quality control, showcasing our state-of-the-art lyophilizers and rigorous protocols designed to uphold the potency and stability of our client’s products.

Brief Overview of Lyophilization

The Steps of Lyophilization:

In the lyophilization process for pharmaceutical manufacturing, there are three broad stages: freezing the product, establishing a vacuum, drying the product under vacuum at a very low temperature. This process results in a freeze-dried cake that can be reconstituted using sterile diluents but can be stored before use.

According to the Office of Regulatory Affairs (U.S. FDA), lyophilization generally includes the following steps:

- The biologic or drug is dissolved in an appropriate solvent, typically water for injectable material

- The bulk solution is sterilized through a 0.22-micron bacteria-retentive filter

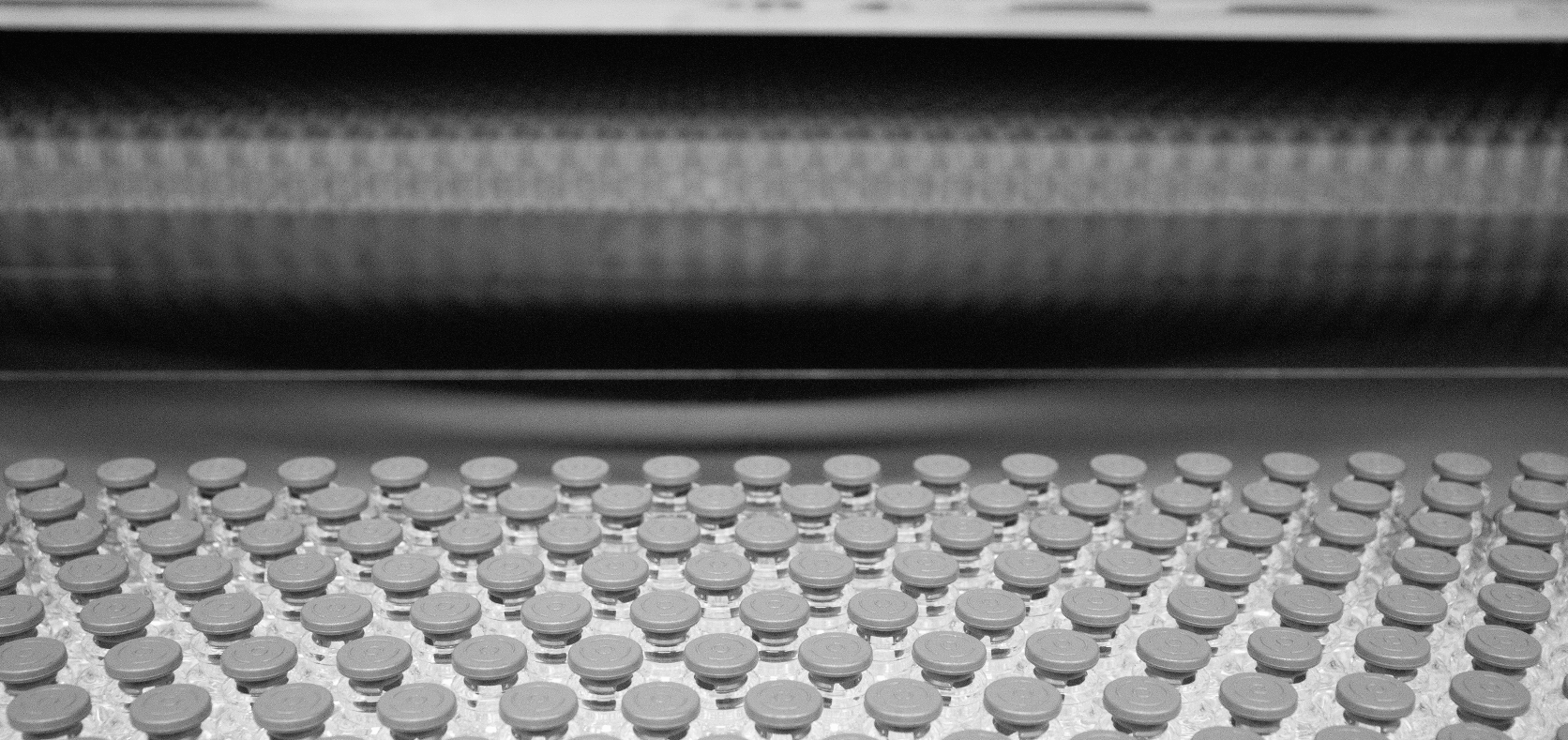

- The solution is then placed in individual sterile containers, typically glass vials, which are then partially stoppered under aseptic conditions

- These partially stoppered vials are transported to the lyophilizer and loaded in under aseptic conditions

- The solution is then frozen within the freeze-drying chamber

- A vacuum is applied to the chamber and, using heat, the water is sublimed from the frozen state

- The vials are completed stoppered, typically using a hydraulic or screw rod stoppering mechanism

Lyophilizer Capabilities at JHS:

JHS currently has eight lyophilizers ready for production use, seven at our Spokane facility and two at our Montreal facility, with plans for an additional lyophilizer available in 2025. Two additional lyophilizers will be qualified by 2026 as part of our ongoing facility expansion in Spokane and one more in Montreal. Our lyophilizers can accommodate vial sizes of 2 mL to 100 mL and batch sizes up to 153,000 vials. They are also equipped with automated CIP and SIP precise cold shelf loading at -45°C and can process up to 300 vials per minute.

Quick Review of Advantages & Disadvantages of Lyophilization

As this is a complex process, there are advantages and disadvantages to lyophilization that each manufacturer and client should be aware of.3

Advantages include:

- Long-shelf-life stability and product stability of the dry powder

- The removal of water without too much heat applied to the product

- An “ease” with processing liquid which then simplifies aseptic handling

- Rapid ability to reconstitute the product safely

Disadvantages include:

- More processing and handling time

- Complex and costly equipment

- Sterile diluent is needed to complete reconstruction

However, this short list of disadvantages has been addressed within the wider pharmaceutical manufacturing industry starting in 2014. The National Institute of Standards and Technology funded the Advanced Lyophilization Technology Hub to “help reduce variability and develop more uniform, consistent, and efficient lyophilization processes”4. This consortium is dedicated to developing new approaches to the lyophilization process, including the design of the equipment, training, instrumentation, and training.

The Lyophilization Process: Step-by-Step

Pre-freezing and Primary Drying in Lyophilization:

Lyophilization begins with pre-freezing the product. This is vital to the process as it safeguards the valuable properties in the product while maintaining its structure before the sublimation of water. At JHS, our products are pre-frozen to a temperature as low as -45°C.

After the product is pre-frozen, primary drying takes place. During primary drying, the product is kept at a low temperature so that the free ice is sublimed away from the solid state under reduced pressure. Sublimation is when the ice crystals pass directly from a solid to a gas without ever becoming liquid, and is completed in these steps:

- The product is frozen

- The lyophilizer chamber is sealed

- The condenser cools

- The vacuum is pulled

- Gentle heating is applied

- Finally, the water vapor escapes from the vials and is frozen onto the condenser

Sublimation in Lyophilization:

During sublimation, the temperature must always be kept below the melting temperature of the product. If the temperature rises too quickly or if it is too high, the product begins to melt which can cause chemical alteration of the product, foaming up or puffing of the product cake, loss of volatile agents, loss of particles as they are boiled, and/or meltback.

Mass transfer then occurs as the sublimation progresses from the surface down as resistance to gas flow increases. After this, heat transfer occurs, which is limited by the maximum tolerable surface temperature of the dry product and the heat conductivity of the dry mass as it undergoes sublimation.

Secondary Drying in Lyophilization:

The next step in the process is secondary drying. Secondary drying happens when the last ice crystal has disappeared, and the product is then cautiously warmed up from its low temperature. This final dehydration of the product is carried out under a high-temperature vacuum that rids the system of any water that did not crystallize and was bound to the product’s molecules. Secondary drying is completed when the residual moisture is low enough to ensure that the product will remain stable until the expiry date.

Post-Drying in Lyophilization:

Once secondary drying is complete, the post-drying process begins with pre-aeration of the product. During pre-aeration, the vacuum is broken with sterile gas before the vials are stoppered. At JHS, this is done using sterile dry nitrogen or another inert gas. If the vacuum is broken with untreated sterile air, the product might absorb oxygen and water vapor. After pre-aeration is complete, the stoppers are sealed into the vials under a slight vacuum. After the stoppers are fully closed, the vacuum is fully broken with sterile air.

The vials are then unloaded and sealed with a color-coded overseal that guarantees product integrity. The seals are color-coded so that the product can be easily identified. Once the vials are sealed and processed, they are inspected for imperfections, including missing stoppers, missing and/or damaged seals, cracked vials, empty vials, foreign matter within the product “cake”, or imperfect cakes/meltback.

The inspection stage is the final stage of the lyophilization process, and the product is now ready to be packaged and shipped to the appropriate client.

The Freeze-Dying Process at JHS

As detailed above, lyophilization requires a complex freeze-drying process that converts the original pharmaceutical solution to the final powdered “cake” that is stable and able to be reconstituted later. Although the freeze-drying process remains similar no matter the manufacturer, it is important to highlight what that process entails here at JHS for our current and future partners.

The Freeze-Drying Components and Initial Steps:

Each lyophilizer contains three major freeze-drying components: the chamber, the condenser, and the vacuum pump(s). At JHS, there are specific steps that go into preparation of the freeze dryer to begin the lyophilization process. It typically takes between 11 and 16 hours to complete the following steps:

- An automatic and fully validated, computer-controlled cleaning system is activated, cleaning the chamber and condenser with hot WFI

- The chamber is sterilized at a temperature of 121°C using a fully validated, computer-controlled automatic steaming system

- Bellows tests are performed to ensure the integrity of the freeze-dryer components

- A vacuum hold test is performed to ensure that the chamber is sealed and will maintain sterility

Once the above process is concluded, the product is prepared with the following steps:

- The product goes through a mechanical pre-treatment where it is filtered and/or clarified

- The product goes through a physical pre-treatment using concentrate dilute solutions or sterilize biologicals

- Lastly, the product goes through a chemical pre-treatment that adjusts its pH and/or adds fillers such as mannitol to increase the dry weight of the product cake

The Product is Loaded in the Lyophilizer:

Once the product is prepared, the next step in the process is for the product to be filled into the vials and loaded into the lyophilizer. The filler is programmed to fill the specific vial size required and the specific freeze-drying recipe for the product is selected for this fill. Once the recipe is selected, the automatic loading system is activated, the filling weight is adjusted, and then filling commences under Grade A conditions. The filled vials are then automatically loaded onto the freeze-drying shelves, also under Grade A conditions. At JHS, the vials are directly loaded onto the frozen shelves, rather than loading the product directly onto the trays. The vials may be loaded onto the ambient, cooled, or frozen shelves.

Each product is frozen in a mixture of water and other substances. Although there are multiple types of freezing utilized in lyophilization, JHS uses contact freezing on cooling plates. This freezing then transforms and hardens the solutions as the “free” water in the solution crystallizes into ice.

Bound water remains in the vial as it is fixed to the internal structure by special bonds. Interstitial fluids now lie between the ice crystals and form a continuous net that contains all the compounds within the original system. The temperature continues to fall, resulting in more water “freezing out”, concentrating the fluids within the vial. The final freezing temperature of the process results in the fluids becoming rigid.

The final freezing process is impacted by the type and number of ice crystals produced at the determined cooling rate. The type, size, and quantity of these ice crystals determine how the product will freeze dry.

Freeze drying the product results in the following advantages:

- It maintains the original shape and texture of the product

- It thoroughly dries the product

- It guarantees the product can be stored and can be easily re-constituted

Challenges and Limitations

Although lyophilization remains the best option for the safe storage and use of biologics and small molecules, there are some challenges and limitations caused by the complex process outlined above. According to Mirasol at Biopharm International, this complex process can become even more complicated, depending on what biological molecules are within the product itself. Sensitive biologics can destabilize if frozen or heated incorrectly, resulting in unsafe and unusable final product. They are also sensitive to various interactions within the lyophilization process which can cause the proteins to unfold, resulting in loss of therapeutic efficiency for the patient2.

Since each product is different, each lyophilization process requires different temperatures and recipes, meaning that every product must be heavily researched and documented to ensure usable results. One final risk is that lyophilization presents a high contamination risk due to the product being exposed for extended periods of time2. Because of this, it is vital that lyophilization is conducted in an ISO 5 environment and that clean-in-place and steam-in-place systems are in place within the lyophilizer.

If these challenges are noted and avoided through proper research and sterile environments, lyophilization remains the best choice for pharmaceutical manufacturing.

The process of lyophilization stands as a cornerstone in pharmaceutical manufacturing, preserving the integrity of biologics and biological products for over 80 years. Through meticulous freezing, drying, and vacuuming stages, lyophilization yields stable pharmaceutical powders with extended shelf lives, pivotal for widespread distribution and safe use. Despite its complexities, advancements in technology and research have mitigated many challenges, propelling the industry forward.

JHS’ commitment to innovation is evident in our state-of-the-art lyophilizers and rigorous quality control measures. By leveraging this technology, JHS ensures the integrity and efficacy of our products, while maintaining their original characteristics and facilitating seamless reconstitution when needed. This commitment to expertise when it comes to our quality control and innovative technology ensures that each of our clients’ projects will be a success.

While challenges such as product sensitivity and contamination risks persist, research and adherence to stringent protocols mitigate these concerns, ensuring the safety and efficacy of lyophilized pharmaceuticals. As we continue to navigate the evolving landscape of pharmaceutical manufacturing, lyophilization remains an indispensable tool that safeguards the potency and stability of pharmaceutical products including biologic products for patients.